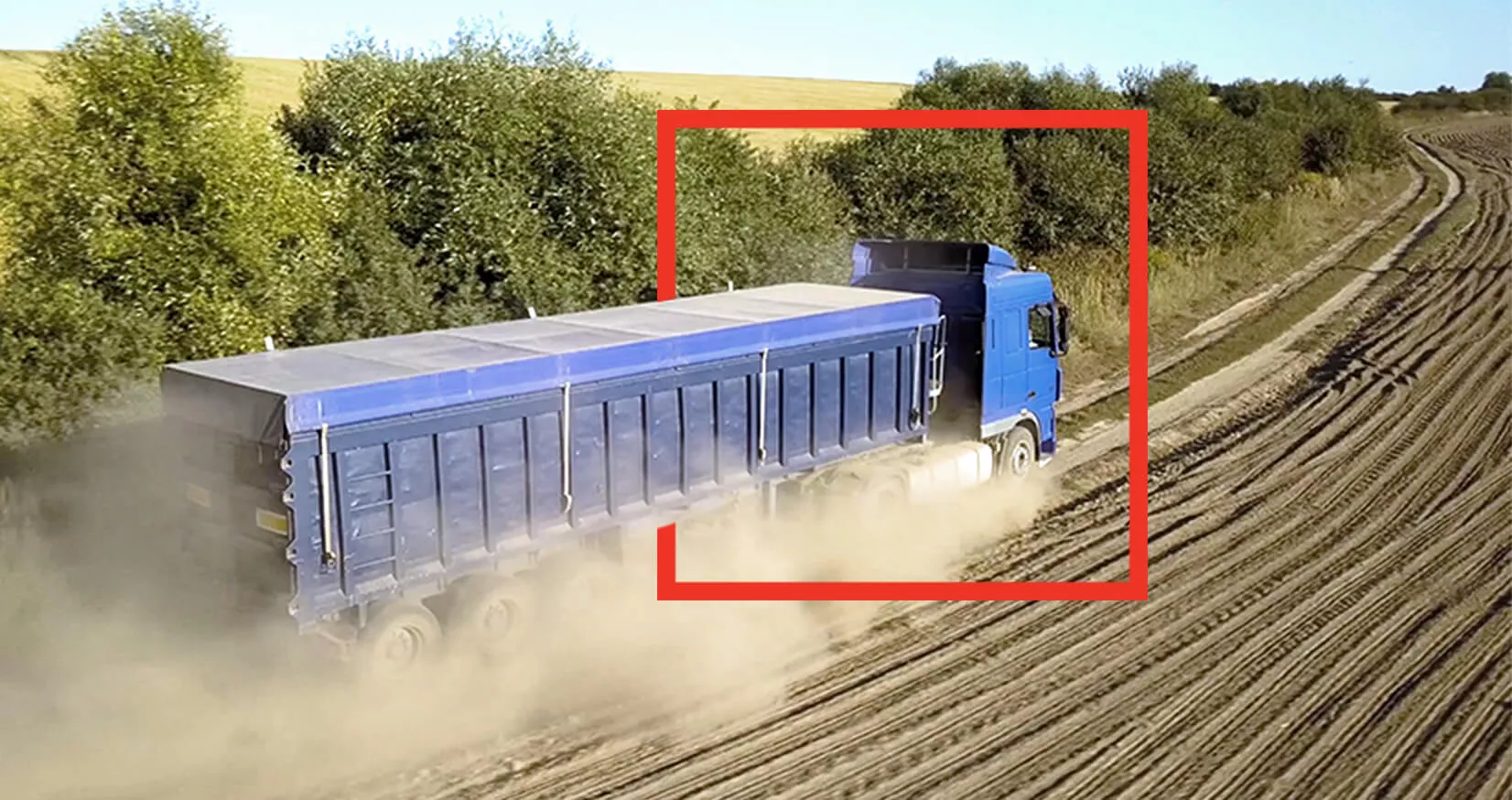

The best way to keep your diesel engines and equipment on the job is to prevent dust, water and other contaminants that cause premature wear and reduce performance from getting in the fuel, air, hydraulic and lube systems.

It’s that simple (theoretically).

In real life, in harsh jobsite conditions and at full speed along a highway, ensuring that diesel engines and equipment operate efficiently and when needed can be a challenge — especially when particles too small for an operator or a service technician to see can infiltrate air intakes, fuel tanks and injectors. These contaminants are so small they are measured in microns, one of which is equal to one-millionth of one meter (0.000001 m).

Typical contaminants include water, sand, pollen, dust, salt and microbes, all of which can shorten service cycles, contribute to unplanned downtime, and drive up ownership costs if not properly filtered.

The types and sizes of contaminants have everything to do with the fuel, air and other filters you choose. The smaller the particles, the higher the quality of filters must be. Choose filters with media designed to handle real-world conditions. Fleetguard tests them to know that the sizes of contaminants to be captured determine what media should be used in a filter.

The diameter of a single strand of the filter media needs to be approximately 1/10 the size of the particles to be captured. We’ve proved this with extensive testing and analysis to understand how filter media works.

Removing contaminants that cause premature wear on critical components is key to prolonging engine and equipment life. Fleetguard can help. We design and manufacture multiple types of filter media to get the job done. These can include cellulose, micro-glass, melt-blown and nanofiber alone or in combinations, depending on the application and original equipment manufacturer’s specifications.

That’s the protection of filtration science.

Basic knowledge about engine and equipment filtration can take you only so far. To maximize equipment performance and life while extending maintenance intervals, you need to better understand some of the industry’s little-known issues. Start with five of the biggest secrets.

READ THE ARTICLE

Rapid biodiesel adoption came at a cost: premature filter plugging shortened service intervals. In response, Fleetguard developed a filter that provided a seven-time increase in performance.

FIND OUT HOW